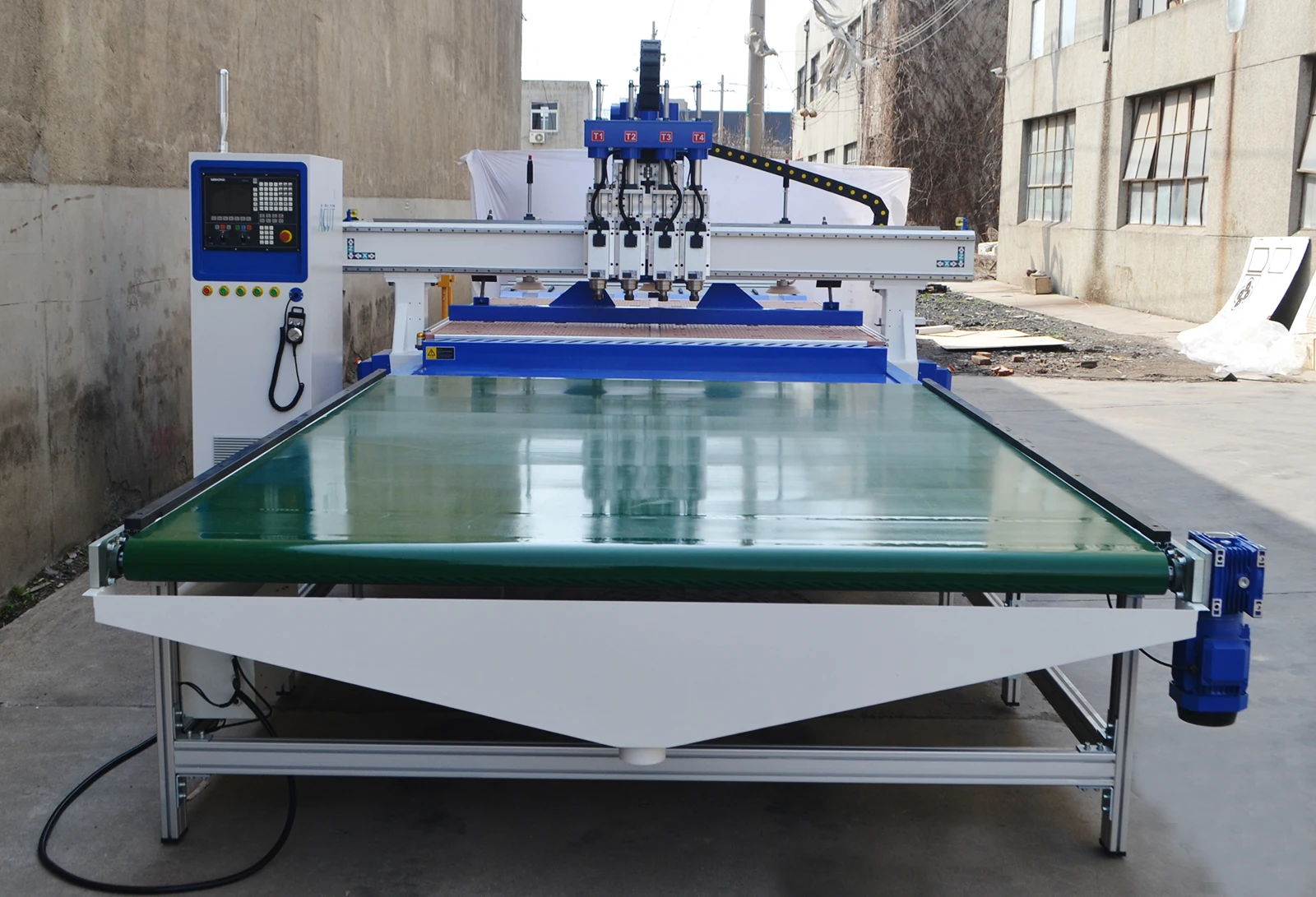

Lintcnc Cnc Router Automatic Loading And Unloading Atc Nesting Furniture Make Machine 1325 1530 2030 For Kitchen Cabinet

Large tool maker

Standard configuration:

Syntec FC control system +Wireless handwheel & Import square guide rail 25mm & Xinyue Gear $Xinbao reducer&Yaskawa Servo Japan & DELTA invert & Y3+X2 Positioning cylinder & 9.0KW ChangSheng air cooling spindle & 7.5kw water cooling vacuum pump & 4.0kw Double-barrel Dust collector & 16 disc change tool & Automatically push

SPECIFICATIONS FOR LT-1325 CNC ROUTER MACHINE | ||||||

Model | ATC LT-1325 wood CNC Router | Inverter | DELTA inverter | |||

Working area | 1300(X)*2500(Y)mm | Max. idling speed | 25m/min | |||

Machine structure | 8mm thickness welded steel tube, cast iron vertical shafts and steel gantry | Max. working speed | 12m/min | |||

Table surface | Double layer vacuum table | Working Accuracy | <0.05/300mm | |||

Spindle | 9.0KW air cooling spindle | Instruction formate | G code *.u00 *.mmg *.plt | |||

Spindle rotating speed | 0-24000rpm/min | Working voltage | AC220V, 1 phase, 50-60Hz | |||

Guide rail | Hiwin linear square guide rail 25mm | Control Cabinet | Independent | |||

Driving method | X,Y axis by helicia gear rack, Z axis by pneumatic | Other | Tool Sensor; Oiling system; Tool Box etc. | |||

Motors and drivers | YASKAWA Servo motor and Servo driver | Compatible software | YUNXI/Type3/Castmate/Coreldraw/AutoCAD and other CAM/CAD software | |||

Control system | Syntec 6MA control system +Wireless handwheel | |||||

Performance feature:

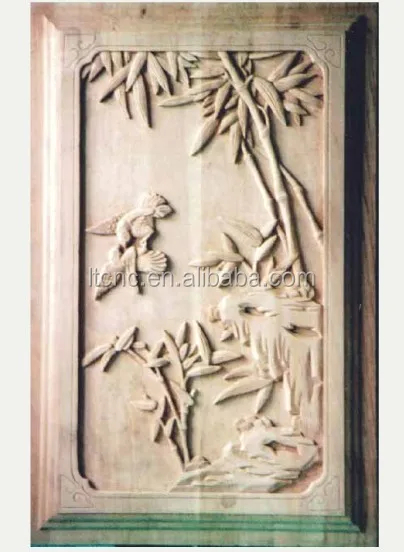

Perfect function, vertical emptying, slotting, material cutting, one-step completion, completely replacing traditional sliding table saws and electronic cutting saws, to get rid of the dependence of the traditional opening mode on labor, and to open the material while using the CNC row drill group to be vertical In the meantime, through the integration with dedicated design software, it can truly realize intelligent production.

2. Advertising Industry: Advertising identification, sigh making, Acrylic engraving and cutting, crystal word making, blaster molding, and other advertising materials derivatives making.

3. Mold Industry: A sculpture of copper, aluminum, iron and other metal molds, as well as artificial marble, sand, plastic sheeting, PVC pipe, wooden planks and other non-metallic mold.

2.Software issue:

Supply technical support for machine lifetime free.

3.Hardware issue:

Main parts(excluding the consumables) shall be replaced/ repaired free of charge if there is any problem during the warranty period.

4.Support online:

our engineer give 1 hours to solve question online.

5.Training in LINTCNC factory:

We are able to train your staff after placed order in our factory for free.

6.Oversea service:

We are able to send technician to your workshop to do the installation and training. You will need bear the

related costs. (flight,visa,hotel,training costs, etc.)

There are English manual or guide video that show how to use machine.

If there is still have any question, we can talk from phone or Skype.

2)Can you recommend a CNC ROUTER MACHINE to me,thanks?

Yes, In order to give you a suitable router machine, please tell me the max working

area, materials for processing and the thickness for materials processing engraving

or cutting. Then perfect suitable CNC router will be recommended.

3) If machine have any problem after I ordered it, how could I do?

Free parts send to you in machine warranty period if machine have any problem.

Free after-sales service life for machine, please feel free contact us if your machine have any problem.

we will give you 24hours service from phone and Skype.

4) MOQ ?

Our MOQ is 1 set machine. We could send machine to your country port directly, please tell us your port

name. There will be best shipping freight and machine price send to you

5)Payment terms

a. 30% by T/T in advance,70% by T/T before shipping

b. L/C is acceptable ,if the amount is big,please issue the draft for our confirmation at first.

Skype: live:.cid.7aeb59350b34f7c7

WhatsApp:+ 86 185 6013 2291

Email: [email protected]