Hicas Industrial Machinery Atc 1325 Cnc Nesting Router Furniture Making Machine

(0)

Perkiraan Waktu Pengiriman:

3 hari

Dijual oleh:

Large tool maker

Large tool maker

Harga:

Rp16.800

/Pc

Pengembalian dana:

Produk Paling Laris

Product Description

Product Parameter

Model | EA48 | UA48 | CA48 | ||

Max. working size | 1220x2440mm(or other customized working sizes) | ||||

Spindle | Chinese brand 9 KW air-cooling ATC spindle, JST or CC, depends on stock | 9 KW air-cooling ATC + 9 V drill unit | |||

X/Y axis transmission | 1.5 module precision helical racks | ||||

Z axis transmission | Taiwan ball screw | ||||

X/Y/Z axis guide rail | Taiwan LAPPING or TIWIN 25mm linear rails | ||||

X/Y/Z axis servo system | Delta or Syntec servo motors and drivers | ||||

X/Y/Z axis reducer | Japanese SHIMPO reducers | ||||

VFD (Inverter) | HPMONT | ||||

Storage of ATC | 12 positions with free 12 ISO 30 type tool holders | ||||

DC power system | Taiwan DELTA | ||||

Main electrical element | Schneider | ||||

Main pneumatic part | AIRTEC | ||||

Working table | Vacuum working table with 6 suction zones | ||||

Control system | Taiwan Delta or Syntec with MPG hand-wheel | ||||

Lubrication System | Automatic lubrication | ||||

Vacuum pump | Equip one 7.5KW water cooling vacuum pump | ||||

Position | Equip 6 (2 front + 4 side) Air Cylinders | ||||

Dust collector | Equip one 4.0 KW with two bags, 380V | ||||

Tool sensor | Equipped | ||||

Option | Add automatic loading,unloading tables/two working tables/pre-labeling | ||||

Details Images

Features:

1. Lathe structure with aging treatment. It can be used for a long time without deformation,and it guarantees high performance.

2. Control interface is more humanized,and is easy to operate.Instead of skilled worker,the operator can work after a simple training.High speed and efficiency lead to high yield.

3. Optional automatic loading and unloading.This machine can load and unload automatically,cut wooden boards optimally, drill vertical holes in once time.Uninterrupted processing achieve output maximum efficiency. Compared with traditional cutting,it can save a lot of labor cost.It only need one person to operate, even one person can operate several devices with zero error,simple operation and high efficiency.

1. Lathe structure with aging treatment. It can be used for a long time without deformation,and it guarantees high performance.

2. Control interface is more humanized,and is easy to operate.Instead of skilled worker,the operator can work after a simple training.High speed and efficiency lead to high yield.

3. Optional automatic loading and unloading.This machine can load and unload automatically,cut wooden boards optimally, drill vertical holes in once time.Uninterrupted processing achieve output maximum efficiency. Compared with traditional cutting,it can save a lot of labor cost.It only need one person to operate, even one person can operate several devices with zero error,simple operation and high efficiency.

4. Automatic labeling can be chosen.When this machine is cutting and drilling, it identify boards in advance, then paste the corresponding bar code on boards.The whole process without human intervention and it really achieves zero error.

5. Delta/SYNTEC high-end CNC machine control system

6. Good stability, fast data processing speed and more accurate signal feedback.

7. Aging treatment of bed and gantry milling

8. The machine has higher stability, high precision and long service life.

9. 9KW high power automatic tool change spindle with large capacity tool magazine

10. With strong cutting ability, it can automatically solve various complicated processing.

11. Taiwan high-power drive system

12. High torque drive, faster processing speed.

13. New generation/Delta high-end CNC machine tool control system

14. Good stability, fast data processing speed and more accurate signal feedback.

15. During the production process of the whole machine and before leaving the factory, it accepts strict quality inspection control and processing test to ensure that the backboard grooves and the front and back holes are accurately drilled. Ensure that the back plateslot and the front and back holes are accurately drilled.

5. Delta/SYNTEC high-end CNC machine control system

6. Good stability, fast data processing speed and more accurate signal feedback.

7. Aging treatment of bed and gantry milling

8. The machine has higher stability, high precision and long service life.

9. 9KW high power automatic tool change spindle with large capacity tool magazine

10. With strong cutting ability, it can automatically solve various complicated processing.

11. Taiwan high-power drive system

12. High torque drive, faster processing speed.

13. New generation/Delta high-end CNC machine tool control system

14. Good stability, fast data processing speed and more accurate signal feedback.

15. During the production process of the whole machine and before leaving the factory, it accepts strict quality inspection control and processing test to ensure that the backboard grooves and the front and back holes are accurately drilled. Ensure that the back plateslot and the front and back holes are accurately drilled.

Company Profile

Our Company:

HICAS group is one leading manufacturing and exporting company of wood working machine in China. We are committed to provide one-stop service to our customers all over the world.

HICAS was established in 2003 with two manufacturing centers in Foshan and Qingdao, covering about 40,000 square meter.

1.Founded in 2003.

2.Owns 2 factories manufacturing nailess plywood box machine, wood pallet machine,wood crate machine, nailless plywood box.

3.Owns 70% Market Share(Nailless plywood box machine) in China.

4.Expertized in R&D, Manufacturing, Marketing,Training, and Service.

5.Professional in consultation of Factory construction and Processing Technology, and Technical Improvement Training.

6.Supply Technical Solution base on Cost Analysis and Optimal Allocation.

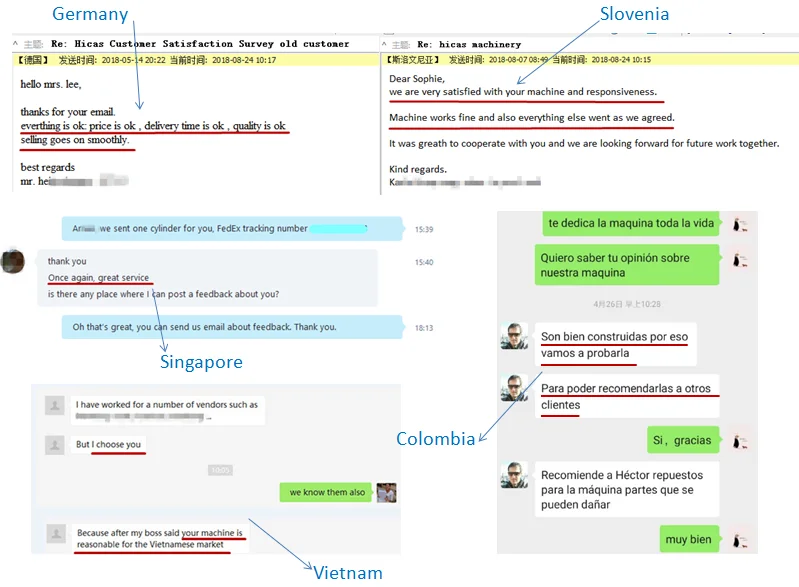

7.Customer and feedback

HICAS was established in 2003 with two manufacturing centers in Foshan and Qingdao, covering about 40,000 square meter.

1.Founded in 2003.

2.Owns 2 factories manufacturing nailess plywood box machine, wood pallet machine,wood crate machine, nailless plywood box.

3.Owns 70% Market Share(Nailless plywood box machine) in China.

4.Expertized in R&D, Manufacturing, Marketing,Training, and Service.

5.Professional in consultation of Factory construction and Processing Technology, and Technical Improvement Training.

6.Supply Technical Solution base on Cost Analysis and Optimal Allocation.

7.Customer and feedback

Product packaging

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

FAQ

1. Do you offer installation?

3. How long can we get replacement parts?

Common spare parts can be delivered by express within one week. Some parts can be purchased locally.

4. What technical support do you offer?

1. Technical support by phone, email or WhatsApp/Skype around the clock.

2. Friendly English version manual and operation video.

3. Engineer available to service machinery overseas.

5. Do you have any machines in our country?

6. Can you customized the machine?

Our machines can be customized made according to buyers’ request.

7. What other machine do you offer?

We provide one-stop shop service of woodworking machines for the buyers. Other kinds of woodworking machines, like sanding machine, CNC router, drilling machine, saw machine can be provided as well.

8. Can you set the system to our language?

Our system supports common languages like Chinese, English, Russian, Spanish, French, German

Our machines are almost assembled before loading in container. It is very easy for installation in your workshop. Video guidance and English manual can be provided freely. Engineers can be sent to service in site if the buyer request. all cost in buyer’s account (the machine quotation does not include this cost), including all transportation cost between China and buyer factory (two way), visa and Insurance cost, hotel and eating in buyer country is responsible by buyer, extra labor salary USD200/day.

2. Where can we get replacement parts?

Most of the spare parts are ready in stock. They will be sent to the buyer directly from our warehouse with original prices.

3. How long can we get replacement parts?

Common spare parts can be delivered by express within one week. Some parts can be purchased locally.

4. What technical support do you offer?

1. Technical support by phone, email or WhatsApp/Skype around the clock.

2. Friendly English version manual and operation video.

3. Engineer available to service machinery overseas.

5. Do you have any machines in our country?

Our machines have been sold to more than 20 countries all over the world, like Russia, Singapore, Uzbekistan, The USA,Malaysia,Peru, Colombia, Vietnam, Slovakia, etc.

6. Can you customized the machine?

Our machines can be customized made according to buyers’ request.

7. What other machine do you offer?

We provide one-stop shop service of woodworking machines for the buyers. Other kinds of woodworking machines, like sanding machine, CNC router, drilling machine, saw machine can be provided as well.

8. Can you set the system to our language?

Our system supports common languages like Chinese, English, Russian, Spanish, French, German

Contact Us

Belum ada ulasan untuk produk ini.

Produk-produk terkait

Rp109.000.000

OSIM uDream - Well-being Massage Chair / Kursi Pijat

Rp26.700.000