Bf-p Panel Furniture Making Machine

global shopping

BF-P panel furniture making machine

heavy automatic nesting wood working center is a set of automatic labeling, automatic feed, automatic processing, automatic blanking function integration of high-end furniture automation production equipment, as well as the model in the original standard machining center + upgrade on the basis of drilling and automatic up-down material accessories, is currently the industry high-end machine, the equipment the back-end specialized docking is composed of five surface drilling and six sides drill and edge banding machine.

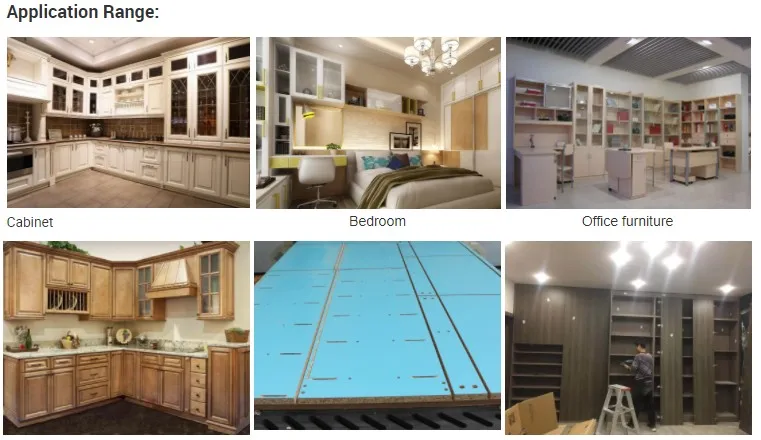

Applicable industries:

1.Furniture: wooden door and furniture, windows, tables and chairs,cabinets and panels, 3D wave plate,MDF,computer desk,musical instruments,etc

2.Advertising: billboard, logo,sign,3D characters cutting,acrylic cutting,LED/neon channel,literal-hole cut,light-box mold,stamp,mound,etc

3.Board processing: insulation, plastic chemical components, PCB, car body, bowling track, ABS, PP, PE, etc.

4.Decoration: Acrylic, PVC, MDF, glass, plastic and soft metals such as copper and aluminum.

Features

·The automatic labeling,automatic loading,cutting optimization,drilling,grooving, zutomatic unloading,perfect combine all these functions in one,achieve maximum efficiency output.

·Labeling and processing tasks can be performed at the same time,simple operation,after simple training,anyone can complete the operation.

·Automatic feeding,cutting,dust,positioning system,which can effectively reduce labor capacity,work intensity,to improve productivity,reduce production costs.