1.PLC system,human-machine interface with Touch screen for easy operation and high accuracy rework.

2.Manage the temperature profiles:setting,storage,application,analysis,debug.Up to 16-segments temperature control,100,000 groups storage for different BGA's rework temperature profile.

3.Control the machine.

Cheap Bga Rework Station Dh-a2 Bga Chip Desoldering And Soldering Machine For Mac Book Computer And Mobile Phone

Molly Mall

Mobile phone repairing machines cellphone repair machine BGA solding station

Specifications | ||||||

1 | Total power | 5300w | ||||

2 | 3 independent heaters | Top hot air 1200w, lower hot air 1200w, bottom infrared preheating 2700w | ||||

3 | Voltage | AC220V±10% 50/60Hz | ||||

4 | Electric parts | 7’’ touch screen + high precision intelligent temp control module + stepper motor driver + PLC + LCD display + high resolution optical CCD system + laser positioning | ||||

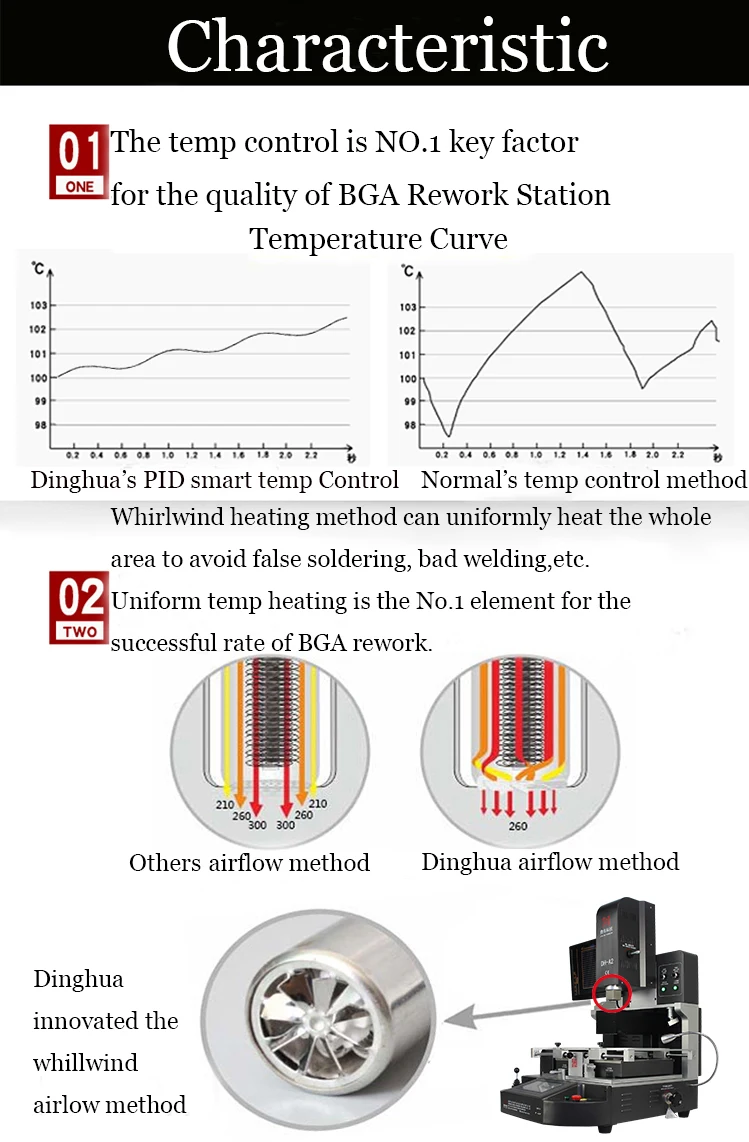

5 | Temperature control | K-Sensor closed-loop + PID automatic temp compensation + temp module, temp accuracy within ±2℃. | ||||

6 | PCB positioning | V-groove + universal fixture + movable PCB shelf | ||||

7 | Applicable PCB size | Max 370x410mm Min 10*10mm | ||||

8 | Applicable BGA size | 1*1mm~80x80mm | ||||

9 | Dimensions | 600x700x850mm (L*W*H) | ||||

10 | Net weight | 70 Kg | ||||

Product Features

◆ Precise optical alignment system

① Color optical system with functions of split vision, two color separation, zoom in/out and micro-adjust, equipped with aberration detection device, with auto focus and software operation

② CCD camera amplify up to 200x, with top/down light brightness adjust function, mounting accuracy is within 0.01 mm

◆ Advanced features

① Top hot air flow is adjustable, to meet the demand of any chips.

② Desoldering, mounting and soldering automatically.

③ Built-in infrared laser positioning, help fast positioning for PCB.

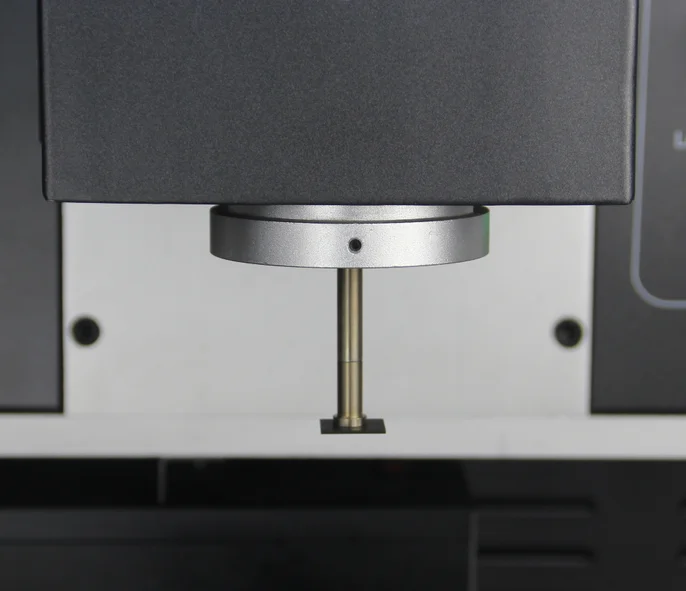

④ Top heating head and mounting head 2 in 1 design.

⑤ Mounting head with built-in pressure testing device, to protect the PCB from being crushed.

⑥ build-in vacuum in mounting head pick up BGA chip automatically after desoldering completed.

◆ Three independently controlled heaters

① top and bottom heaters are hot-air heating, the third is infrared preheating zone, the top and bottom heaters can set 8 segments rising temperature/constant time/temperature rising slope , can save tens of thousands of groups temperature curves.

② it can heat PCB board and bga chips at the same time. And the third IR heater can preheat the PCB board from bottom evenly, to avoid PCB from deformation during repair process. All three heaters can heat independently .

③ It uses k-type thermocouple closed-loop control and PID automatic temperature compensation system, together with PLC and temperature module to enable precise temperature deviation to ±2 degree centigrade.

④ The external sensor can detect temperature precisely, analyze and calibrate the real temperature curve accurately at any time.

◆ Multi-functional ergonomic system

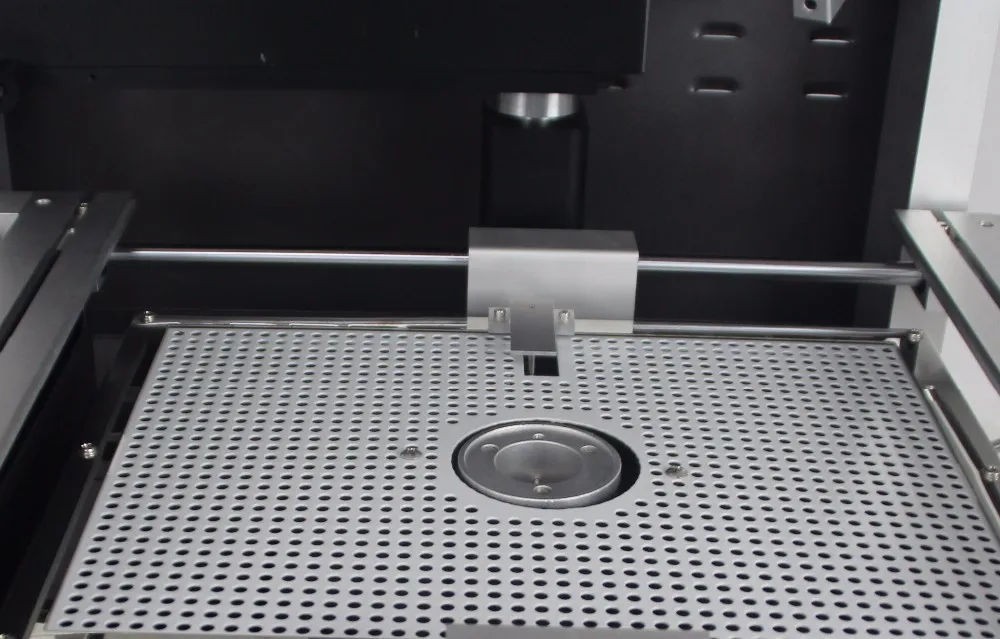

① bottom heater can be adjusted up and down.

② Adopted all kinds of magnetic top and bottom nozzles, with 360° rotation, easy for installation and replacement, customized sizes are available.

③ Multi-functional PCB support shelf, can be moved along X axis, together with universal fixture and V-groove bracket, suitable for all kind of PCB positioning.

④ powerful cross-flow fan automatically cool the PCB board fast after desoldering or soldering completed, it can prevent the heaters from aging. Fan will be shut down automatically when the heaters temperature drops to normal temperature.

◆ Superior safety functions

Machines are CE certification guaranteed. It is equipped with emergency button. Also there is voice warning around 5 seconds before soldering/desoldering process complete. With automatic power-off protection device when abnormal accident happens, with a double over-heating protection control.

Smart PC(Brains of machine)

Optical Alignment

Name:CCD Camera Lens

Brand:Panassonic

Origin:Japan

1.Effectively increase the accuracy of alignment and success rate of repairing.

2.Image dispayed on monitor screen.

Built-in infrared laser positioning, help fast positioning for PCB board.

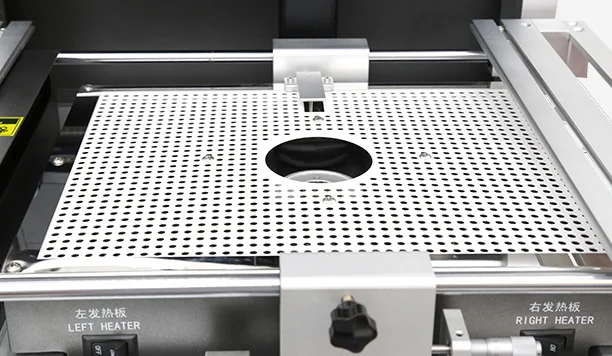

Three independent Heaters(3 Temp Zones)

1.Top Hot Air +Bottom Hot Air+Infrared preheating platform.The top and bottom can be moved upward/downward.

2.Make heating focusd and even.Effectively increase rework rate.

Manual & Automatic Mode

1.Manual:Joystic (①to right/left----camera images zoom in/out.② up/down ----top heater up/down)

2.Just press one botton to start soldering/desoldering/mounting process.

Plus size infrared preheating zone, covered with steel mesh

Packing List

1. Machine:1 set

2. All packed in stable and strong wooden cases,suitable for import and export.

3. Top nozzle:3 pcs (31*31mm,38*38mm,41*41mm)

Bottom nozzle:2pcs(34*34mm,55*55mm)

4. Beam:2 pcs

5. Plum knob: 6 pcs

6. Unicersal fixture:6 pcs

7. Support screw:5 pcs

8. Brush pen:1 pcs

9. Vacuum cup:3 pcs

10. Vacuum needle:1 pcs

11. Tweezer:1 pcs

12. Temp sensor wire:1 pcs

13. Professional Instruction Book:1 pcs

14. Teaching CD: 1 pcs

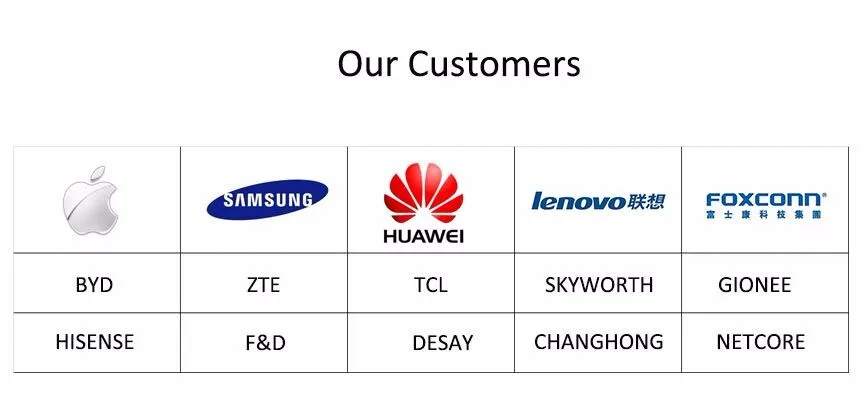

SHENZHEN DINGHUA TECHNOLOGY DEVELOPMENT CO.,LTD is a professional manufacturer of welding equipments. Our products: bga rework stations, automatic soldering machines, automatic screwdriving machines, welding kits and SMT materials etc. Our mission: “Research as basis, Quality as core, Service as guarantee” .

To ensure the quality, Dinghua was the first to pass UL, E-MARK, CCC, FCC, CE ROHS certificates. Meanwhile, to improve and perfect the quality system, Dinghua has passed ISO, GMP, FCCA, C-TPAT on-site audit certification.

Science and technology are the primary productive forces, with over years of hardworking, Dinghua has owned core technology of temperature controlled and 38 patents and finished the development and production of manual, semi-auto and automatic series and realized the second revolution from traditional hardware combination to integrated control.Our products have been exported to Europe , America, Southeast Asia, Australia, Africa, the Middle East, Taiwan and more than 80 countries and regions and established the relatively sales network and terminal services system.We are becoming the pioneer and guide of SMT welding industrial and our products have been applied in individual maintenance, industrial and mining enterprises, teaching and research work,military manufacturing industry and aerospace industry and so on, which has treed good reputation among users.

![Asus ROG Zephyrus G14 GA403UU-R745OL6G-O Gaming Laptop - Gray [14.0" 3K OLED 120Hz/R7-8845HS/RTX4050 6G/16GB/1TB SSD/RGB/WIN11/OHS21]](http://globalshoppingoss.oss-cn-hongkong.aliyuncs.com/globalshop/uploads/172432324271003114.png)